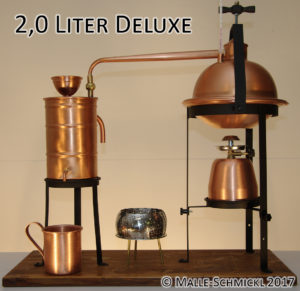

Still DELUXE, 3.8 Liters, complete with steam thermometer, gas burner and large aroma kettle

Preis 758€

DELUXE Still (2, 3.8 or 7.8 liter)

- The still is made of solid, high-quality copper. The still was designed by us and is optimally designed from a process technology perspective. The distillation device is manufactured exclusively for us.

- The still can be ordered in the 2 liter, 3.8 liter or 7.8 liter version. Each can be converted to the other kettle sizes. Hence you then have a still with two or three different pot sizes (original Malle-Schmickl still system).

- A gas burner for plug-in gas cartridges (standard size 190 g) is used as a heat source. It can be regulated continuously by means of a setting wheel.

- The cooling system consists of an approximately 1 m long copper tube in a spiral shape and a copper container that is open on top so that the water content can be exchanged manually if there is no running water available. The container has an inlet by means of a funnel for connection to a water tap, and an outlet nozzle. It is also possible to operate the cooling system by means of a small recirculation pump (not included in delivery), similar to indoor fountains.

- The still is delivered with detailed operating instructions, so that you can start distilling immediately without any problems.

- The kettle is sealed by means of a screw-on lever, and a sealing ring ensures that there are no leaks.

- Dimensions: width 29 cm, length 70 cm, height 69 cm (without thermometer)

- The still can also be used for the distillation of beer, wine, herbs or for making essential oils (e.g. lavender oil, lemon oil, mint oil etc.) by means of steam distillation.

Distilling schnapps with the Deluxe still

- A distillation process with the gas burner takes approximately 30-45 minutes for the 2 liter kettle size. Depending on the alcohol content of the material to be distilled, you can produce 2 to 6 liters of high-proof schnapps per process with a 7.8 liter still. The measuring kit is recommended for dilution to drinking strength.

- Because of the supplied burn protector – this principle was developed by us in 1998 – it is not necessary to filter the mash before distilling. Nevertheless, when the heating power is changed there is no annoying time delay as there is with a jacketed kettle. Unfiltered mashes produce a higher yield and more flavor in the distillate, because the softened fruit pulp contains a lot of alcohol and flavorings.

- The flavor basket that we also developed in 1998 is used for making spirits: Add spices, herbs or fruits to the basket, such as raspberries (for Raspberry brandy)), aniseed (for ouzo, raki), juniper berries (for Dutch Jenever) or spice mixtures based on juniper (for gin) or alternatively wormwood (for absinthe ) etc.. When distilling wine or schnapps with less flavor such as vodka and grain schnapps, the alcohol vapor picks up the flavorings from the basket and you will get excellent spirits.

- The heads and tails are separated using a thermometer. We have worked with this separation method since the mid ‘90s, because it enables more accurate and reliable separation than other methods, especially with small stills. Since the middle of the 2000s, experts have regarded this method as standard for the separation of heads and tails, and not just for small stills. The thermometer has a range from 0 to 110 °C and can be read accurately down to 0.5 of a degree. The measuring point is located at the highest point of the vapor that has not yet cooled, because it is only here that the vapor temperature is independent of the respective still construction and hence correlates to the actual alcohol content of the distillate. The correct position of the measuring point is particularly important, because incorrect positions can lead to differences of up to 10 °C or more!

- The kettle size of 2 liters is ideal for trying out your own spirits recipes and for mash quantities of up to 10 liters per type. The 3.8 liter variant is for mash quantities of 10 to 15 liters per type of fruit. Alternatively, for larger quantities of spirits, the 7.8 liter kettle is optimally suited for mash quantities of more than 20 liters. A distilling kettle should be at least half filled for each distilling process; otherwise there will be a loss of yield and flavor.

- For double distilling, the 7.8 liter kettle is used for the raw distillate, and the 2 or 3.8 liter kettle is for the fine distillate.

- In our book "The Artisan’s Guide to Crafting Distilled Spirits" you will find many tips and instructions as well as around 100 recipes for tasty brandies and spirits.

Distillation of essential oils with the Deluxe still

- Steam distillation can be performed with the 2 liter, 3.8 liter or 7.8 liter kettle. If you would like to make hydrosols, then the kettle size is aligned with the quantity of plants. All three pot sizes are suitable for hydrosols. For the distillation of essential oils, you need the 7.8 liter pot, because only here can you fit in enough plant material to actually obtain essential oil.

- The flavor basket that we developed in 1998 is used for making high-quality essential oils and hydrosols. With this insert, the materials being distilled, i.e. the flowers, seeds, roots or herbs, are not boiled in the water, but rather steamed. Therefore it ONLY comes into contact with the steam.

- Filling volume for the material being distilled: Since unlike the LEONARDO®, the Deluxe still does not have a separate vapor space, the specified kettle size corresponds to the maximum filling volume of the material being distilled PLUS the amount of water added. Hence, 5.8 liters of the material being distilled can be placed in the 7.8 liter kettle if there are 2 liters of water under it.

- The still deliberately has NO automatic oil separator or separating funnel. First of all, this is because considerable quantities of oil stick to the insides of this type of equipment, so no oil is lost unnecessarily. Secondly because some oils are heavier than water (e.g. cinnamon, cloves, alant root, balsam poplar and so on), and thirdly because the container with the hydrosol and essential oil should be stored for at least several weeks BEFORE separation in order to obtain the highest possible quality oils and hydrosols possible. Apart from this, the hydrosols obtained are often so intensive that depending on the plant type, they often exhibit very opaque and milky cloudiness, or there are accumulations of oil drops in the bottom area. Hence with automatic oil separation, considerable amounts of the valuable oil would not be separated. Even with crystal clear hydrosols, you should wait at least several hours before you separate the oil from the hydrosol.

- LEONARDO® or Deluxe still? If you only want to make essential oils and hydrosols, i.e. no alcohol, then the LEONARDO® is the right choice. If you want to distil both alcohol and essential oils or hydrosols in the same still, then the Deluxe is best suited for this.

- In our book “BOOK: The Essential Oil Maker's Handbook The Essential Oil Maker’s Handbook” (not included in delivery), you will find many tips and guides that go far beyond the operating instructions such as, for example, the right part of the plant, the optimum harvest and harvesting time (time of day) and the best processing methods for more than 140 native and exotic plants in order to obtain the most intensive hydrosol possible and high oil yields. Furthermore, there are more than 50 basic recipes for using the essential oils and hydrosols. The selection ranges from products for facial and body care, liqueurs, spiced oils, flavoring for tea, and inhalations to room sprays, sauna infusions and perfume.